How to choose Crawler Mucking Loader?

I. Industry Background and Market Status of Crawler Mucking Loader

In the fields of mining, tunnel excavation, and underground construction, the Crawler Mucking Loader (a type of crawler material handling machine) serves as a core material handling equipment. With its flexible terrain adaptability and efficient loading capacity, it has become an indispensable equipment in modern mechanized construction. Unlike traditional open-pit loaders, the Crawler Mucking Loader adopts a low-profile body design and a crawler walking structure, specifically tailored for narrow underground operation spaces. It can perform loading, transportation, and unloading operations in coordination, significantly replacing manual operations, reducing safety risks, and enhancing construction efficiency.

From market data, the global Crawler Mucking Loader industry is showing a steady growth trend.

II. Core Technologies and Product Classification of Crawler Mucking Loader

2.1 Core Technology Composition

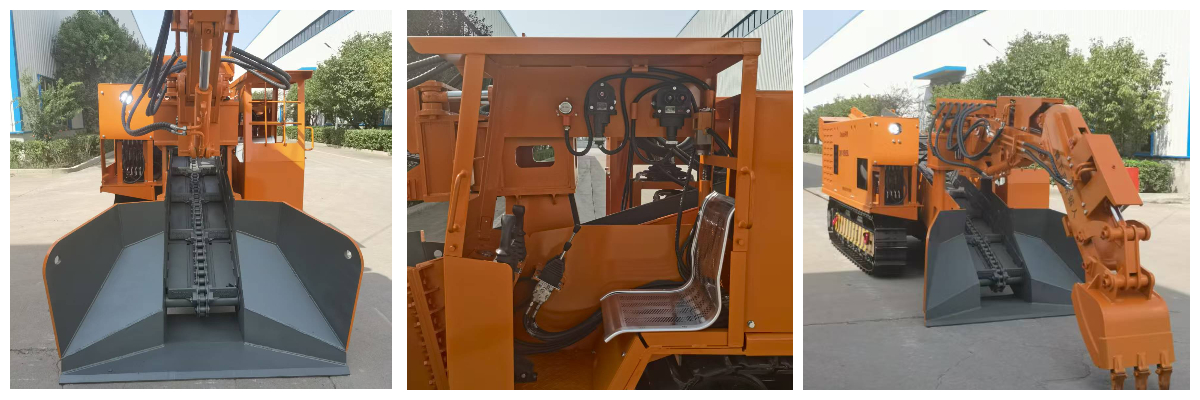

A high-performance Crawler Mucking Loader needs to integrate multiple system core technologies to ensure stable operation in complex conditions. Its core technology system includes: the hydraulic system is responsible for driving the bucket, conveying device, and crawler walking, using a pilot valve control method, which enables precise operation and flexible steering, and also has shock resistance capabilities; the crawler walking system adopts a lubricated crawler belt design, with adjustable tension, combined with wear-resistant excavator accessories, improving the equipment's passability and service life on uneven terrain; the electrical control system realizes automated operation control, and some high-end models support fault self-detection and remote monitoring functions, reducing maintenance costs. Additionally, some Crawler Mucking Loader can be equipped with hydraulic breaker hammers to perform multi-functional operations such as rock crushing and tunnel trimming, expanding application scenarios.

2.2 Main Product Classification and Application Scenarios

According to the requirements of the working terrain and slope, Crawler Mucking Loader are mainly divided into two categories to meet different construction scenarios:

Steep Slope Crawler Mucking Loader: Suitable for working environments with a slope of ≤32°, with a slope range of +20° to -32°, mainly used for loading operations in mine tunnels, semi-coal rock tunnels, railway tunnels, and underground caverns in engineering. This type of machine usually has stronger climbing ability and load stability, and can work in conjunction with coal mining hydraulic drills to achieve mechanized mining processes, adapting to large-section engineering requirements through different tonnage configurations.

Flat Terrain Crawler Mucking Loader: Suitable for flat working surfaces with a slope of ≤16°, widely used for material loading in semi-rock tunnels, small tunnels, and water conservancy projects. Its structure is compact and the operation is flexible. It can efficiently unload materials to transfer equipment such as dump trucks, belt conveyors, and mine cars. The unloading height can be customized according to customer requirements, balancing operational efficiency and space adaptability.

III. Core Selection Factors for Crawler Mucking Loader

3.1 Clearly define requirements based on the operating scenario

The first step in selecting a Crawler Mucking Loader is to match the characteristics of the operating scenario. Key factors to evaluate include the slope of the operation, the width and height of the roadway, the type of materials (rock, debris, coal, etc.) and the loading capacity requirements: For large slope mining operations, prioritize models with a climbing ability of ≥ 30° and a ground contact length of ≥ 2500mm to ensure operational stability; For narrow roadway operations, pay attention to the height and width of the equipment body, and choose models with a low body design to avoid space limitations affecting operation; When handling hard rock materials, it is necessary to equip with wear-resistant buckets and hydraulic crushing devices to enhance equipment durability.

3.2 Evaluate equipment performance and core component quality

Equipment performance directly determines construction efficiency and operation and maintenance costs. Core evaluation indicators include loading capacity, conveying efficiency, power system stability and operational convenience: The loading capacity should match the daily material volume of the project to avoid equipment overload or capacity waste; The conveying device should have an automatic cleaning function to reduce the risk of faults caused by residual materials; The power system should prioritize the use of well-known brand engines and hydraulic components to ensure stable power output, while reducing fuel consumption and failure probability. In addition, models controlled by pilot valves are more flexible in operation, reducing the intensity of manual operation and improving operational accuracy.

3.3 Consider manufacturer strength and after-sales guarantee

For B2B buyers selecting a Crawler Mucking Loader, the technical strength, production scale and after-sales system of the manufacturer are crucial. Prioritize manufacturers with a complete industrial chain layout, as they have stronger upstream component procurement and midstream complete machine integration capabilities, better product quality and more controllable costs, with a gross profit margin typically ranging from 20% to 40%, and better cost performance. At the same time, it is necessary to confirm whether the manufacturer provides customized services, such as adjusting unloading height and accessory adaptation, to meet individualized operation needs; The complete after-sales guarantee includes overseas technical support, spare parts supply and maintenance training, which can significantly reduce the risk of equipment operation and maintenance overseas.

IV. Industry Development Trends of Crawler Mucking Loader

The development prospects of Crawler Mucking Loader are promising. With the promotion of infrastructure construction and the replacement of manual operations with mechanization in mines, the market demand is steadily increasing. The compound annual growth rate of the industry from 2026 to 2030 is approximately 9.5%, and the market size is expected to reach 11.2 billion yuan by 2030. The industry is accelerating its transition towards greening and intelligence. The proportion of electric models is continuously increasing, and unmanned and remote control technologies are gradually commercialized. The demand for medium and large-sized equipment is growing significantly. The industry's concentration is constantly improving, and the leading enterprises occupy the majority of the market share. At the same time, the export pace of domestic Crawler Mucking Loader is accelerating, with Southeast Asia and Africa being the core growth markets. The industry also faces issues such as reliance on imported core components and homogeneous competition at the mid-to-low end. In the future, enterprises with core technologies and global service capabilities will have greater competitive advantages.

V. FAQ - Common Questions and Answers about Crawler Mucking Loader

Q1: How to determine the suitable tonnage for Crawler Mucking Loader?

A1: It needs to be determined comprehensively based on the average daily material handling volume of the project, the size of the roadway, and the capacity of the transportation equipment. At the same time, ensure that the equipment size matches the transportation vehicles and the space of the roadway. According to actual needs, additional tools such as impact hammers can be installed.

Q2: What are the key points of daily maintenance for Crawler Mucking Loader?

A2: The daily maintenance of the Crawler Mucking Loader focuses on the core system. Daily checks include verifying the tension of the tracks, the level of hydraulic oil, and the sealing performance, as well as cleaning the oil and dirt. Bolts of the operating mechanism's pin shafts are tightened, and the wear condition of the bucket teeth is inspected. The engine oil, braking sensitivity, and electrical safety components are checked. Lubricating grease is added to the hinge points and bearings in accordance with regulations. After operation, the equipment is leveled, power is cut off for protection, and rain and dust prevention measures are taken.

Q3: Can large slope and flat terrain Crawler Mucking Loader be used interchangeably?

A3: It is not recommended. Although large slope models can operate on flat ground, they have higher energy consumption, heavier and less flexibility; flat terrain models have a climbing ability of ≤ 16°, and operating in a large slope environment is prone to loss of control, posing safety hazards, and the loading efficiency significantly decreases. Therefore, the corresponding model must be selected based on the slope of the operation.

Q4: What compliance issues should be considered when purchasing Crawler Mucking Loader overseas?

A4: It is necessary to confirm that the equipment complies with the industry standards of the target country (such as EU CE certification, North American EPA certification); pay attention to import tariffs and trade barriers, and communicate with the manufacturer in advance about whether the quotation includes tariffs and customs clearance fees; ensure that the operation manual and maintenance documents provide versions in the target country language, and confirm that the manufacturer has compliance service capabilities for overseas after-sales.

VI. Call to Action

Choosing an appropriate Crawler Mucking Loader is the key to improving the efficiency and controlling costs of mining and tunnel engineering. As a professional manufacturer specializing in mining equipment, Shandong Kechuang Equipment Manufacturing Co., Ltd. has a complete Crawler Mucking Loader R&D, production, and overseas service system, and can provide a full range of large-slope and flat terrain models, supporting customized technical solutions and global spare parts supply. No matter what terrain your project is located in or what load requirements it has, our technical team will provide you with one-on-one selection guidance to help you precisely match the equipment with the operation scenario. Contact us immediately to obtain the exclusive Crawler Mucking Loader selection plan and quotation, and embark on an efficient and safe mechanized construction journey!

Contact Us

WhatsApp: +8615264873047

Official website: https://www.cresicsmining.com/

Email: cresicsmining@gmail.com