How to pick the right Coal Mine Drilling Machine?

I. Background and Market Status of the Global Coal Mining Industry

With the continuous increase in global energy demand, the efficiency and safety level of coal mining have become the focus of attention for global coal mining enterprises. Coal Mine Drilling Machine (a core equipment in the coal mining process) directly determines the progress, safety and economy of the mining operation, and is highly favored by global B2B buyers. As a professional manufacturer of coal mine drilling machines, we rely on independent research and development and a mature manufacturing system to provide Direct Factory Supply (factory direct supply) services to the global market. With high reliability and high cost-effectiveness, our Coal Mine Drilling Machine helps global coal mining enterprises reduce costs and increase efficiency, achieving sustainable mining.

In recent years, although renewable energy has developed rapidly, coal still occupies an important position in the global energy structure, especially in industrial power generation and steel smelting, where its demand has maintained a steady growth. At the same time, global coal mining enterprises have put forward higher requirements for the quality, reliability and after-sales service of Coal Mine Drilling Machine. Due to the complex mining environment, high humidity, dust and high pressure underground, ordinary drilling machines are prone to failure, affecting the mining progress. Therefore, a Coal Mine Drilling Machine with anti-wear, anti-corrosion, strong stability has become the first choice for global buyers. In addition, the factory direct supply model, with the advantages of reducing intermediate links, high cost-effectiveness, short delivery cycle, etc., has gradually become the mainstream choice for international B2B buyers to purchase Coal Mine Drilling Machine.

II. Core Technologies and Product Advantages of Coal Mine Drilling Machine

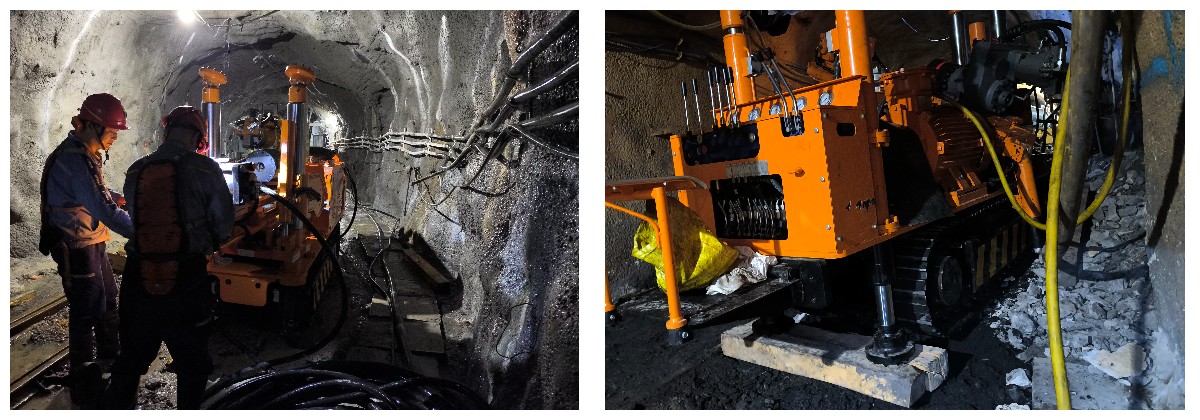

As a manufacturer specializing in the research and production of coal mine drilling machines, we always focus on technological innovation and combine the different scenarios of global coal mining to create Coal Mine Drilling Machine series products with strong adaptability and excellent performance. At the same time, we cover related long-tail products such as Coal Mine Drilling Rig and Tunnel Drilling Rig (tunnel drilling machine), providing comprehensive solutions for global buyers' diverse needs.

(1) Core Technology Features

1. Intelligent Control Technology: Our Coal Mine Drilling Machine is equipped with an advanced intelligent control system, which can precisely control the depth, speed and pressure of the drilling. Operators can complete the operation remotely, effectively reducing the number of underground workers and improving operational safety. At the same time, the equipment has a fault automatic diagnosis function, which can monitor the equipment operation status in real time and issue fault warnings in time, reducing the equipment failure rate.

2. Efficient Drilling Technology: Using high-strength drill pipes and wear-resistant drill bits, combined with optimized drilling structure design, the drilling efficiency of Coal Mine Drilling Machine is more than 30% higher than that of traditional equipment. The drilling accuracy error is controlled within ±5mm, and it can meet the drilling requirements of different coal layers and geological conditions. Whether it is shallow coal layer mining or deep coal layer exploration, it can perform stably.

3. Resistance to harsh environments: For the complex working environment in coal mines, we have carried out special protective treatment for the Coal Mine Drilling Machine. The equipment shell is made of corrosion-resistant and shock-resistant high-strength steel, and the internal electrical components have waterproof, dustproof, and explosion-proof functions. It can operate stably for a long time in environments with humidity above 85% and high dust concentration. The service life is 20% longer than the industry average.

(II) Core Product Advantages

1. Direct supply from factory, high cost-effectiveness: We adopt the supply model of "manufacturer to buyer", eliminating the intermediaries such as agents and distributors, and passing on the profits directly to the buyers. For the same configuration of Coal Mine Drilling Machine, our price is 15%-25% lower than the market counterparts. At the same time, we support batch customization, and can adjust the equipment parameters and configurations according to the specific mining needs of buyers to meet personalized purchasing requirements.

2. Reliable quality, international certification: All Coal Mine Drilling Machines undergo strict quality inspection processes, from raw material procurement, production processing to finished product delivery. Every step is controlled by professionals to ensure that the product quality meets international standards. The products have passed ISO9001 quality management system certification, CE certification, and other international authoritative certifications, and can smoothly enter major markets worldwide without concerns about compliance issues.

3. Full series coverage, wide adaptability: Our products not only include conventional models of Coal Mine Drilling Machine, but also cover small portable Coal Mine Drilling Rig, large deep mining Coal Mine Drilling Rig, and Tunnel Drilling Rig suitable for coal mine tunnel construction. They can be adapted to different scales and mining scenarios of coal mining enterprises, whether it is small private coal mines or large multinational coal mining groups, there will be suitable products.

III. Manufacturing and Application Process of Coal Mine Drilling Machine

To enable global B2B buyers to have a clearer understanding of our products, the following briefly introduces the manufacturing process and application process of Coal Mine Drilling Machine, helping buyers clearly grasp the production standards and usage scenarios of the product.

(II) Manufacturing Process

1. Raw material procurement and inspection: Select high-quality high-strength steel, wear-resistant alloys, imported electrical components, etc. All raw materials undergo strict quality inspection to ensure they meet the product design standards, ensuring the quality of the equipment from the source.

2. Core component production and processing: Use high-precision processing equipment such as CNC lathes and milling machines to process the drill rods, drill bits,Fuselage,etc. of the core components to ensure precise dimensions and solid structure; at the same time, critical components undergo heat treatment to enhance their wear resistance and corrosion resistance.

3. Equipment assembly and debugging: Precisely assemble the processed components and install core modules such as intelligent control systems and hydraulic systems; after assembly, conduct comprehensive performance debugging to simulate the coal mine underground operation environment and test various indicators such as drilling efficiency, stability, and safety of the equipment to ensure it meets the factory standards.

4. Quality inspection and delivery: Conduct final quality inspection on the Coal Mine Drilling Machine that has passed the assembly process, including appearance inspection, performance inspection, and safety inspection. After passing the inspection, issue a quality inspection report, package it for storage, and prepare for shipment.

(II) Application Process 1. Preparations: Based on the specific requirements of coal mining, determine the installation location of the Coal Mine Drilling Machine, clear the debris in the operation area, check the various parameters of the equipment, and ensure that the equipment is in a normal operating state; at the same time, provide professional training to the operators to familiarize them with the operation procedures and safety precautions of the equipment.

2. Drilling operations: Operators use the intelligent control system to set the depth, speed and pressure of the drilling, start the equipment for drilling operations; during the operation, monitor the operating status of the equipment in real time, adjust the drilling parameters in time to ensure the drilling accuracy and efficiency. For deep coal seams or complex geological conditions, Coal Mine Drilling Rig can be combined for auxiliary drilling to improve the stability of the operation.

3. Post-maintenance: After the drilling operations are completed, clean and maintain the Coal Mine Drilling Machine, remove dust and debris from the equipment surface, check the wear of the drill rods, drill bits, etc., and replace the damaged parts in time; at the same time, inspect and repair the electrical and hydraulic systems of the equipment to ensure that the equipment can operate stably for the next operation.

Ⅳ. Global Trend Analysis of Coal Mine Drilling Machine Market

Based on the current global energy structure and the development status of the coal mining industry, in the coming years, the global Coal Mine Drilling Machine market will present three obvious trends, providing new procurement directions and opportunities for international B2B buyers.

First, intelligence and automation will become the mainstream trend. As global coal mining enterprises' requirements for operation safety and efficiency continue to increase, traditional manual-operated Coal Mine Drilling Machines will gradually be replaced by intelligent and automated equipment. In the future, Coal Mine Drilling Machines with functions such as remote control, automatic drilling, fault diagnosis, and data networking will become the core of market demand, effectively reducing the number of underground operation personnel, lowering the rate of safety accidents, and improving mining efficiency.

Second, environmental protection and energy conservation demands are prominent. Global environmental policies are becoming increasingly strict, and the environmental requirements of the coal mining industry are also constantly improving. Coal Mine Drilling Machines that are environmentally friendly, energy-saving, and low-carbon will be favored by more buyers. We will continue to increase investment in environmental technology research and development, optimize the power system of the equipment, reduce energy consumption and noise, and reduce dust emissions during operation, helping global coal mining enterprises achieve green mining.

Third, customization and diversification demand growth. Different regions and different-sized coal mining enterprises have significant differences in mining scenarios, geological conditions, and production capacity requirements, and their configuration and parameter requirements for Coal Mine Drilling Machines are also different. In the future, customized procurement will become the main procurement mode for international B2B buyers, and the demand for related long-tail products such as Coal Mine Drilling Rig and Tunnel Drilling Rig will continue to grow, forming a diversified product demand pattern.

Ⅴ. Call to Action: Choose us, win the global coal mining market

As a professional manufacturer of Coal Mine Drilling Machines, we have provided high-quality Coal Mine Drilling Machines, Coal Mine Drilling Rigs, Tunnel Drilling Rigs and other products to coal mining enterprises in 50+ countries and regions around the world. With our independently developed core technologies, strict quality control system, factory direct supply price advantage, and comprehensive after-sales service, we have received unanimous recognition and praise from global buyers.

Whether you are a small coal mining enterprise or a large multinational coal mining group, whether you need regular models of Coal Mine Drilling Machines or customized mining equipment, we can offer you cost-effective products and professional services. Contact us now and enjoy exclusive purchasing discounts, free access to detailed product parameter manuals and quotations, as well as professional technical consultation and customized purchasing plans.

Send an email to our official email address immediately, or call our international sales hotline to get in touch with us. Let our Coal Mine Drilling Machines help your coal mining enterprise improve mining efficiency, reduce operating costs, and seize the broad opportunities in the global coal mining market! We look forward to establishing a long-term and stable cooperative relationship with you and moving forward together to create brilliance!