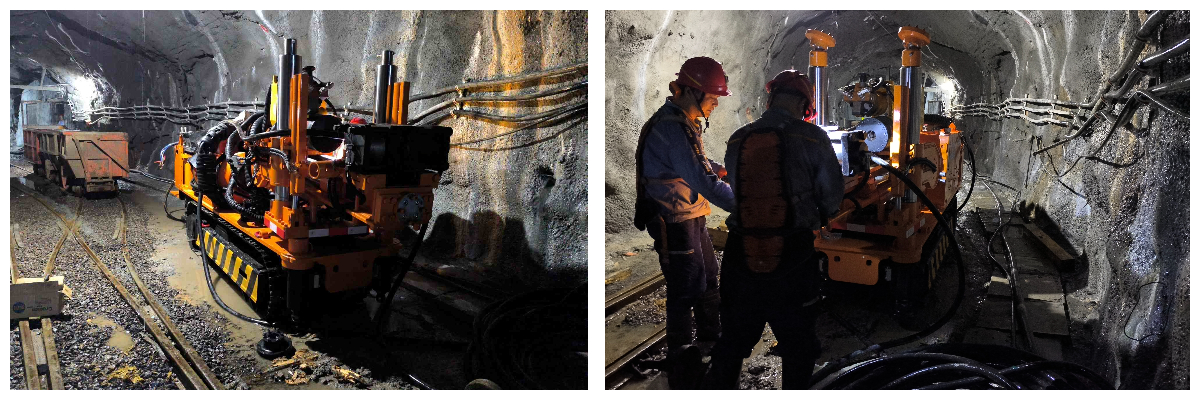

Coal Mine Drill

1.Integrated functions of gas drainage drilling, water exploration & drainage drilling, and deep geological core drilling

2.Crawler travel mechanism, capable of adapting to various complex terrains such as soft and muddy ground

3.Full-attitude drilling capability---Multi-position, multi-angle, and multi-height drilling operations

Product Details

The Coal Drilling, as the core part of geological exploration and disaster prevention before coal mining, its operation efficiency and safety directly determine the overall efficiency of mining projects. The series of drilling equipment launched this time precisely covers the general drilling needs of Coal Mine Drill and the specialized underground drilling requirements of Underground Coal Mine Drill. They are key equipment for modern coal mining with safety and efficiency.

The equipment adopts a fully hydraulic drive system and is equipped with a high-power power unit. The drilling efficiency is increased by more than 30% compared to traditional equipment. It can easily penetrate coal layers and various complex rock layers and is suitable for different drilling depths. In response to the characteristics of narrow underground spaces, Underground Coal Mine Drill adopts a modular and compact design. The body width is less than 1000mm, and it is equipped with a crawler-type walking mechanism, with a maximum climbing ability of ±18°. It still has excellent maneuverability in rough tunnels and low coal seams.

In terms of safety performance, the equipment integrates multiple protective mechanisms and is equipped with functions such as gas concentration monitoring, overload protection, and emergency braking, effectively avoiding risks in underground operations from the source. At the same time, it is equipped with an intelligent drilling measurement system that can display the drilling trajectory in real time, with a measurement accuracy of ±0.15°, ensuring precise drilling positioning. This series of Coal Mine Drills can flexibly achieve various processes such as rotary drilling and directional drilling, and are widely used in scenarios such as gas extraction, water exploration, and geological structure exploration, achieving "one machine for multiple uses".

The various components of the equipment are easy to disassemble and assemble, with low maintenance costs. The hydraulic components are selected from high-quality standard products, ensuring strong stability. Its efficient drilling capability, flexible environmental adaptability, and reliable safety guarantee provide comprehensive technical support for underground mining operations, helping to enhance mining efficiency and ensuring the safety of workers.

Parameters

Project | Unit | ZDY1250LPS | ZDY1900LPS | ZDY2400LPS | ZDY3200LPS | ZDY4500LPS | ZDY6500LPS | ZDY8000LPS | ||

Slewing gear

| Nominal Torque | N.m | 1250 | 1900 | 2400 | 3200 | 4500 | 6500 | 8000 | |

Rated Speed | r/min | 48-220 | ||||||||

Feed | KN | 120 | 150 | 180 | 210 | |||||

Lift-off Force | KN | 150 | 180 | 230 | 280 | |||||

Give The Process | mm | 850/650 | ||||||||

Dip Angle Of Hole | ° | ±90 | ||||||||

Borehole Diameter | mm | 50/63.5 | 63.5/73 | 73/89 | ||||||

Drilling Depth | m | 100 | 150 | 300 | 400 | 500 | ||||

Minimum Working Height | mm | 1200 | ||||||||

Maximum Workingheight | mm | 2200 | ||||||||

Running Gear | Working Pressure | MPa | 25 | |||||||

Speed of travel | m/min | 0-30 | ||||||||

Climbing capacity | ° | 18 | ||||||||

Hydraulic Power Unit | Power Of Motor | Kw | 20 | 30 | 37 | 45 | 55 | 75 | 90 | |

Nominal Working Pressure | MPa | 25 | ||||||||

Dimensions(Length*Width*Height) | mm

| ≤3350*850*1750 | ≤3550*950*1900 | ≤3850*1050*2000 | ||||||

Weight Of The Machice ±5% |

kg | 3300 | 3500 | 4000 | 5000 | 5800 | 6800 | 7500 | ||

Q&A (Coal Drilling Equipment)

⭕Q1: As a direct manufacturer, how do you guarantee the equipment's quality and cost-effectiveness?

A1: We are the direct source manufacturer of this coal drilling equipment. All hydraulic components are selected from high-quality standard products for strong stability; core parts undergo strict factory testing to avoid quality defects. Meanwhile, cutting out middlemen allows us to offer competitive factory-direct prices with no hidden costs, and easy-to-disassemble components reduce your long-term maintenance expenses.

⭕Q2: How does this equipment solve the core pain points of low efficiency and poor adaptability in underground coal mining?

A2: Targeting low drilling efficiency, our equipment uses a fully hydraulic drive system to boost efficiency by over 30% vs traditional models, easily penetrating coal and complex rock layers. For narrow underground spaces, its compact design (width < 1000mm) and crawler walking mechanism (±18° climbing capacity) ensure great maneuverability in rough tunnels and low coal seams—no need to worry about site restrictions.

⭕Q3: What after-sales support and safety guarantees can you provide for global clients?

A3: On safety: the equipment is equipped with gas monitoring, overload protection and emergency braking to eliminate underground risks from the source, plus a high-precision measurement system for accurate drilling. On after-sales: we provide global technical guidance, quick supply of standard replacement parts, and on-site service support in key regions. As a source factory, we offer timely, reliable after-sales services without delays caused by third-party agents.

A wide range of multi-purpose models are available for your selection.