How to Choose a Coal Mine Mucking Loader Manufacturer?

In the current era where the global coal mining industry is undergoing a transformation towards efficiency, safety, and sustainability, Coal Mine Mucking Loader, Coal Mine Slag Scraper, and Coal Mine Mucking Machine are the core equipment for underground operations, directly determining the mining efficiency, operational safety, and operating costs. For international B2B buyers, choosing a high-quality manufacturer is not only crucial for ensuring equipment quality but also a fundamental prerequisite for achieving long-term stable cooperation and reducing investment risks. This article will combine industry background, market data, technological trends, and practical points to provide a comprehensive manufacturer selection guide for global coal mining enterprise buyers, helping to accurately identify reliable partners.

I. Industry Background and Market Status: Coal Mine Mucking Loader Sees New Development Opportunities

Currently, the global coal mining industry is facing two core changes: First, safety and environmental protection policies are becoming increasingly strict, with various countries introducing regulations to limit underground human operations, driving the upgrade of equipment such as Coal Mine Mucking Loader and Coal Mine Slag Scraper towards explosion-proof, low emissions, and intelligentization; second, mining scenarios are becoming increasingly complex, with increased demand for deep mining and narrow tunnel mining, placing higher requirements on the mobility, adaptability, and efficiency of equipment. Against this backdrop, the product iteration speed of Coal Mine Mucking Machine has been continuously accelerating, and the technical strength, production capacity, and service level of manufacturers have become the core elements that distinguish competitiveness.

II. Core Product Technology Analysis: Understanding the Core Competitiveness of Coal Mine Mucking Loader

For B2B buyers, the technical performance of the equipment is the primary consideration when choosing a manufacturer. Although Coal Mine Mucking Loader, Coal Mine Slag Scraper, and Coal Mine Mucking Machine all belong to the equipment for coal mine slag removal, they have different application scenarios and technical characteristics. The technical strength of the manufacturer directly determines the operational efficiency and service life of the equipment.

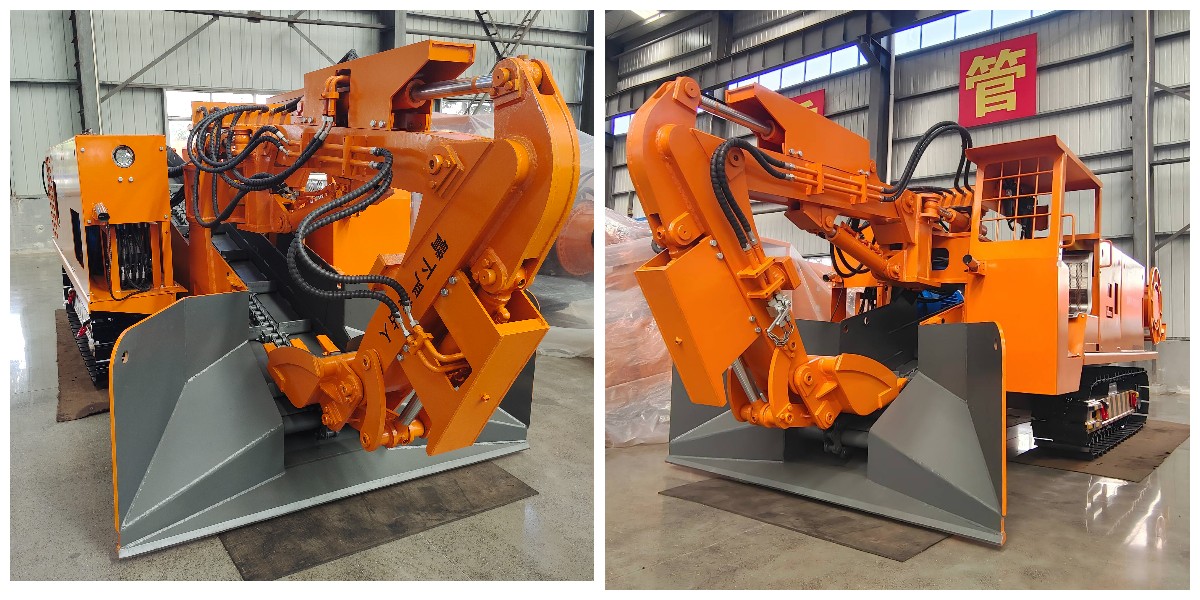

Coal Mine Mucking Loader is also known as the coal mine rock loading machine. It is a multi-functional underground operation equipment that integrates excavation, transportation, loading, and operation. It is mainly used for loading ore and waste rock in coal mine tunnels and quarries. It is suitable for complex scenarios such as narrow tunnels and high-gas mines, and is the "main force" of underground operations in coal mines. A high-quality Coal Mine Mucking Loader should have three core technical characteristics: First, excellent explosion-proof performance, equipped with explosion-proof motors and electrical components; second, strong maneuverability, using chassis designs such as crawler or tire type, the crawler chassis has strong grip and is suitable for rough terrain, while the tire type chassis has flexible steering and fast operation, with low maintenance costs and can be flexibly adapted to different tunnel scenarios; third, high efficiency, using a full hydraulic drive system and high-strength buckets, the operational efficiency can reach 120–300 tons per hour, and it is equipped with an intelligent control system, enabling remote control and automatic obstacle avoidance, significantly reducing labor costs.

Coal Mine Slag Scraper fills the gap in waste slag removal in narrow spaces and corner areas. The trackless slag scraper does not require tracks and can move freely, with flexible operation, suitable for scenarios with variable waste slag positions and narrow and uneven tunnels, but has relatively weak carrying capacity. In addition, the short-wall slag scraper is suitable for shallow coal seams and narrow tunnels, with a streamlined body design, capable of flexibly navigating through small spaces and avoiding damage to the tunnel rock walls.

Coal Mine Mucking Machine has a large loading capacity and high conveying efficiency, and can be used in conjunction with drilling machines and coal mining machines to achieve integrated mining and slag removal operations. According to the conveying method, Coal Mine Mucking Machine is mainly divided into two types: scraper conveyor type and belt conveyor type. The scraper conveyor type is suitable for medium and short-distance slag removal, while the belt conveyor type is suitable for long-distance slag removal, with a conveying distance of up to 200 meters or more.

III. Industry Development Trends: Core Competitiveness Orientation for Manufacturers

When choosing a manufacturer of Coal Mine Mucking Loader, not only should attention be paid to the current equipment quality and technical level, but also the industry development trends should be predicted to select a partner with sustainable R&D capabilities and the ability to keep up with industry upgrades. Currently, the global Coal Mine Mucking Loader industry presents three clear development trends, which are also important manifestations of the core competitiveness of manufacturers.

First, the trend of intelligent upgrading. With the accelerated promotion of coal mine intelligent construction, the penetration rate of Coal Mine Mucking Loader products with L2-level or higher autonomous driving functions continues to increase, reaching 18% in 2025, an increase of nearly 12 percentage points compared to 2021. In the future, the demand for underground loading equipment with autonomous driving capabilities will also gradually increase.

Second, the trend of green and low-carbon. Driven by the "dual carbon" goals and environmental protection policies, the coal mining industry is accelerating its transition towards green and low-carbon. Zero-emission and low-noise electric Coal Mine Mucking Loaders have become the mainstream in the market. Therefore, manufacturers need to possess the research and development capabilities of new energy power systems and launch electric and hybrid Coal Mine Mucking Loaders and Coal Mine Slag Scrapers to meet the environmental protection needs of different buyers.

Thirdly, the trend of customization and integrated services. Different coal mines have differences in mining scenarios, tunnel dimensions, and waste residue types, and the specifications and performance requirements for Coal Mine Mucking Loaders also vary. High-quality manufacturers need to have strong customization capabilities and be able to design and produce equipment that is tailored to the specific needs of buyers; at the same time, they should provide integrated services, including equipment installation and commissioning, operator training, after-sales maintenance, and spare parts supply. Especially for international buyers, a complete overseas after-sales service is of vital importance, which can effectively reduce equipment operation and maintenance costs and ensure the continuity of operations.

IV. Core Considerations for Selecting Coal Mine Mucking Loader Manufacturers

Based on the current industry situation and technological trends, international B2B buyers should focus on the following five core factors when choosing Coal Mine Mucking Loader manufacturers. They should comprehensively evaluate the strength of the manufacturers to avoid making hasty choices.

(1) Company Size and R&D Capability

The company has a modern production base and a professional R&D team. It has been dedicated to technological innovation in the field of equipment manufacturing for a long time and possesses a complete R&D, production, and testing system. We continuously invest in technological upgrades and possess a number of independent intellectual property rights and patented technologies, which can meet the customized needs of different customers. With stable production capacity, strict quality control, and strong technical support, we provide reliable products and efficient services to customers, laying a solid foundation for long-term cooperation.

(2) Production Capacity and Quality Control

Production capacity determines the supply capability of the manufacturer, especially for B2B buyers who engage in bulk purchases. It is necessary to ensure that the manufacturer can deliver equipment on time. Buyers can obtain information about the manufacturer's production scale, production line configuration, annual production capacity, etc., to assess its production capacity; at the same time, they should pay attention to the quality control system. High-quality manufacturers usually have a complete quality control process, from raw material procurement, production processing, finished product testing to factory acceptance, with strict standards at every stage to ensure that the equipment quality meets international standards.

(3) Customization Capability and Product Adaptability

Different coal mines have significantly different operating scenarios, and standardized equipment often cannot fully adapt. Therefore, the customization capability of the manufacturer is crucial. Buyers can explain their mining scenarios, tunnel dimensions, waste residue types, and operational efficiency requirements to the manufacturer to assess whether it can respond quickly and design an appropriate Coal Mine Mucking Loader or Coal Mine Mucking Machine solution; at the same time, they should understand the manufacturer's customization cycle and customization costs to ensure that the customized solution meets the requirements and is within the budget. For example, for narrow tunnel mining, the manufacturer can customize a low-profile Coal Mine Mucking Loader with a height of less than 1.7 meters to ensure that the equipment can flexibly navigate through the tunnel; for high-gas mines, a non-explosive Coal Mine Slag Scraper can be customized, equipped with an efficient explosion-proof system to ensure safe operations.

(4) After-sales Service and Overseas Support

As a large underground equipment, Coal Mine Mucking Loader has a long service life and high maintenance requirements. A complete after-sales service is crucial to ensure the long-term stable operation of the equipment, especially for international buyers. When choosing a manufacturer, buyers should focus on its after-sales service system, including the distribution of after-sales service outlets, the configuration of the maintenance team, the supply capacity of spare parts, and the response time; at the same time, they should understand whether the manufacturer provides installation and commissioning, operator training, remote fault diagnosis, regular maintenance and other value-added services to help buyers quickly master the equipment operation skills and reduce maintenance costs. High-quality manufacturers usually provide 24-hour after-sales response services. Overseas buyers can quickly solve problems arising during equipment operation through online communication, video guidance, etc.; at the same time, they can set up spare part warehouses in major export regions to ensure timely supply of spare parts and reduce equipment downtime.

(5) Cost-effectiveness and Cooperation Intention

For B2B buyers, cost performance is an important consideration, but it should be noted that "cost performance" is not simply about low prices, but a comprehensive balance of equipment quality, technical performance, after-sales service and price. Buyers can compare the product quotations, technical parameters, and after-sales service plans of multiple manufacturers to avoid blindly pursuing low prices and choosing manufacturers with substandard quality and poor services. Otherwise, it may lead to high equipment failure rates and increased operation and maintenance costs, resulting in even greater losses. At the same time, they should pay attention to the sincerity of the manufacturer's cooperation, whether it can provide reasonable quotations, flexible payment methods, complete cooperation plans, and long-term stable cooperation support to achieve mutual benefit and win-win results. For example, some manufacturers can offer discounts on spare parts, free maintenance, and other preferential policies to long-term cooperative buyers, improving the cost performance of the cooperation.

V. Call to Action: Choose Quality Manufacturers, Achieve a Win-Win Future in Coal Mine Mining

Coal Mine Mucking Loader, Coal Mine Slag Scraper, and Coal Mine Mucking Machine are the core equipment for coal mine mining. Their quality and performance directly affect the mining efficiency, operational safety, and operating costs. Choosing a high-quality manufacturer is the key to ensuring the equipment value and achieving long-term stable cooperation. In the global wave of intelligent and green transformation of the coal mining industry, it is recommended that international B2B buyers combine the considerations proposed in this article and comprehensively evaluate the technical strength, production capacity, customization ability, and after-sales service of the manufacturers, avoid falling into the trap of low prices, and choose partners with sustainable development capabilities and the ability to provide integrated solutions.

If you are looking for a reliable manufacturer of Coal Mine Mucking Loader, please contact us - we have years of experience in the research, production, and export of coal mine slag removal equipment, a complete R&D team, advanced production lines, and strict quality control systems, and can provide Coal Mine Mucking Loader, Coal Mine Slag Scraper, and Coal Mine Mucking Machine that meet international standards, support customized design, provide integrated services such as installation and commissioning, training, and after-sales maintenance worldwide, helping you reduce investment risks and improve operational efficiency. Contact us immediately to obtain customized solutions and detailed quotations, and join hands to seize the new opportunities in the coal mining industry!