Coal Mine Mucking Loader

1. It integrates excavation, transportation and loading functions, with strong adaptability.

2. The body is compact and flexible, capable of operating in narrow passages.

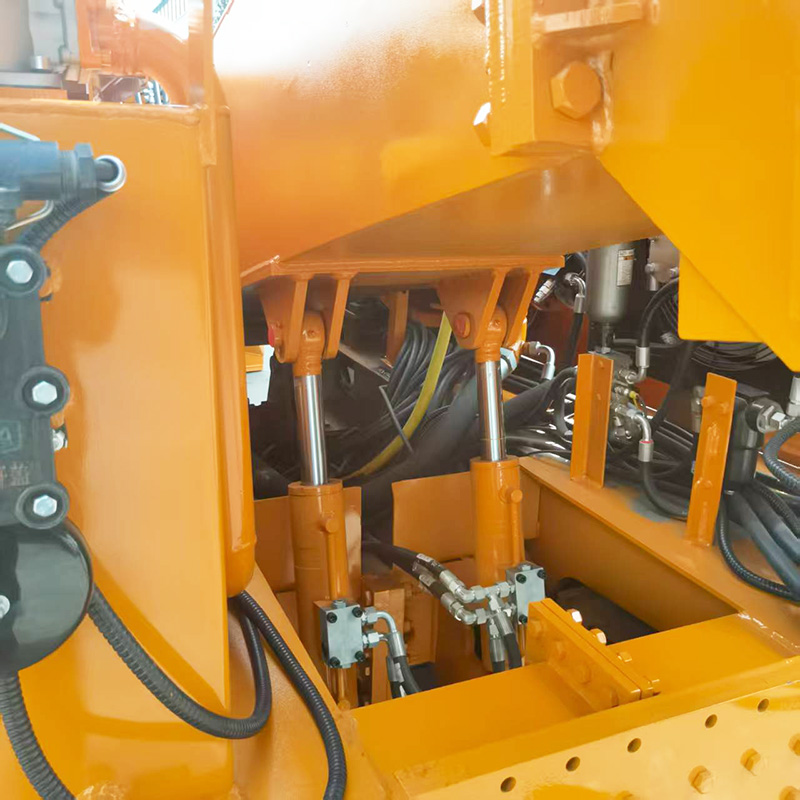

3. Fully hydraulic explosion-proof design, suitable for high-risk underground environments.

4. Significantly reduces manpower and has outstanding overall benefits.

Basic Information

The Coal Mine Mucking Loader (commonly known as a slag-digging machine) is a continuous and highly efficient mining equipment specifically designed for use in underground mines and tunnels. It integrates functions of excavation, slag removal, transportation, and loading, and is the core equipment for mine excavation and slag removal.

I. Equipment Type and Positioning

⭕Core Positioning: Underground / Tunnel Continuous Loading and Discharging Equipment, replacing manual and simple machinery, suitable for narrow tunnels (typically ≥ 1.8×1.8m).

⭕Structural Classification:

●Traveling: Track-type / Wheeled, adaptable to complex underground terrain.

●Power: Electric fully hydraulic (explosion-proof, low noise, environmentally friendly, mainstream in underground environments).

●Conveying: Scraper / Belt Conveyor, directly connected to mine cars / shuttle cars / belt conveyors.

●Industry Classification: Mining Machinery → Underground Mining → Loading and Transportation Equipment (distinguished from open-pit loaders).

II. Core Functions (Features)

⭕Continuous Rock Removal

The mechanical hand (standby claw / rock-digging claw) continuously removes the blasted minerals / rock debris without any interruption, covering the entire working area.

⭕Efficient Material Transportation and Loading

The built-in conveyor directly transports the materials to the mine car, shuttle car or belt conveyor, integrating the processes of excavation, transportation and loading, eliminating the need for secondary transportation.

⭕Coal Mine Chamber Cleaning and Leveling

It can clean the working face, level the coal mine chamber, and remove leftover materials. It has multiple functions in one machine.

⭕Adaptability to Narrow Spaces

The machine body is narrow and has flexible steering, suitable for small and medium-sized cross-section coal mine chambers, filling the gap of mechanized slag removal in narrow spaces.

⭕Safe and Explosion-proof Operations

It uses mine-used explosion-proof electrical equipment, compatible with coal mines / metal mines with gas and dust environments.

III. Core Benefits for the Mining Industry

⭕Significant Improvement in Production Efficiency

●Single machine hourly production capacity is 50–60 m³, replacing 30+ manual slag removal operations, with an efficiency increase of over 10 times.

●Continuous operation, reduced waiting time, and a 30%–50% reduction in tunneling cycle time, resulting in a significant increase in monthly production volume.

⭕Direct Reduction in Operating Costs

●Labor costs: 1–2 operators, replacing a large number of manual workers, saving tens of thousands of yuan in labor costs annually.

●Energy consumption and maintenance: Electric hydraulic is more energy-efficient than fuel; the structure is simple and easy to maintain, reducing downtime.

●Material loss: Precise extraction, less spillage, improved resource recovery rate, and reduced waste.

⭕Safety and Improvement of Working Environment

●Reducing personnel's stay at dangerous work sites, significantly lowering the injury rate, and reducing accident compensation and production downtime.

●Mechanization replacing heavy manual labor, reducing labor intensity, and improving underground working conditions.

⭕Comprehensive Economic Benefits

●The initial investment can typically be recovered within 1–2 years through benefits such as labor, efficiency, and safety.

●Improving the mechanization and intelligence level of the mining industry, enhancing long-term competitiveness and compliance.

Parameters

Item | ZWY-80/30L | ZWY-80/37L | ZWY-80/45L | ZWY-100/45L | ZWY-120/65L | ZWY-150/55L | ZWY-180/75L | ZWY-220/75L | |

Main Technical Parameters | |||||||||

Applicable Section (Width × Height) m | 3.2×2.2 | 3.5×2.5 | 4×2.5 | 4.8×3.2 | 5.4×4.0 | 5.8×4.5 | 6.2×5 | 7.5×5.5 | |

Applicable Axis Width* | (-16° ~ +16°) | (-20° ~ +20°) | ( -32° ~ +32°) | ||||||

Loading Capacity m³/h | 80 | 100 | 120 | 150 | 180 | 220 | |||

Control Mode | Hydraulic Pilot Control | ||||||||

Main Motor Power KW | 30 | 37 | 45 | 55 | 75 | ||||

Digging Width mm | 3200 | 3500 | 4000 | 4600 | 5400 | 5800 | 6200 | 7000 | |

Digging Distance mm | 1500 | 1600 | 1800 | 2150 | 2500 | 3300 | |||

Digging Height mm | 1800 | 2200 | 3000 | 3500 | 3800 | 4000 | 4300 | ||

Digging Depth mm | 400 | 500 | 800 | 990 | 1050 | ||||

Unloading Height (Adjustable) mm | 1200 | 1450 | 2000 | ||||||

Unloading Distance (Adjustable) mm | 1150 | ||||||||

Max. Rotation Angle* | ±36° | ±45° | ±55° | ||||||

Max. Transport Material Size mm | < φ500 | < φ580 | < φ625 | < φ780 | |||||

Boom Structure | Single Boom | Single Boom (or Double Boom) | Double Boom | ||||||

Hoisting Speed m/min | 44 | ||||||||

Track Gauge (Adjustable) mm | 890 | 890 | 900 | 1110 | 1190 | 1400 | |||

Travel Speed m/s | 0.5 | ||||||||

Ground Clearance mm | 300 | ||||||||

Min. Turning Radius m | ≥ 5 | ≥ 7 | ≥ 8 | ||||||

Ground Pressure MPa | ≤ 0.1 | ||||||||

Rated Working Pressure MPa | 23 | ||||||||

Max. Bucket Size | Length mm | 3350 | 4200 | ||||||

Width mm | 850 | 900 | 1000 | 1100 | 1200 | ||||

Height mm | 1200 | 1400 | 1500 | 1650 | |||||

Max. Bucket Weight Kg | 2300 | 3000 | 3500 | ||||||

Max. Overall Dimensions (Working) | Length mm | 6000 | 6500 | 6800 | 7000 | 7500 | 8800 | ||

Width mm | 1750 | 1800 | 2200 | 2350 | 2640 | ||||

Height mm | 1750 | 1750 | 1800 | 2900 | 3250 | 3600 | 3800 | 4200 | |

Machine Weight Kg | 7600 | 8000 | 8200 | 11200 | 13800 | 15200 | 17800 | 20000 | |

Application scenario

⭐Mining operations

●Metal mines: Coal mines, copper mines, gold mines, lead-zinc mines, aluminum mines, etc., with underground horizontal tunnels, inclined shafts, and vertical shafts for slag removal.

●Coal mines / Non-metal mines: Coal mines (requiring explosion-proof equipment), phosphate mines, gypsum mines, limestone mines, etc., with underground excavation operations.

⭐Tunnel Engineering

●Transportation tunnels: Excavation and material removal for highway tunnels, railway tunnels, and subway sections.

⭐Hydropower Engineering

●Excavation and removal of materials for diversion tunnels, diversion tunnels, underground powerhouses, and spillway tunnels.

⭐Municipal and other underground projects

●Excavation of materials from narrow underground spaces such as urban utility tunnels, underground garages, civil defense projects, and mining filling tunnels.

⭐Special Scenarios

●Inclined shafts / vertical shafts: Steep slopes (maximum about 32° for crawler type), vertical / inclined slag discharge.

●Small cross-section / single-headed tunnels: Narrow body, short arm type is suitable for spaces no larger than 1.5m.