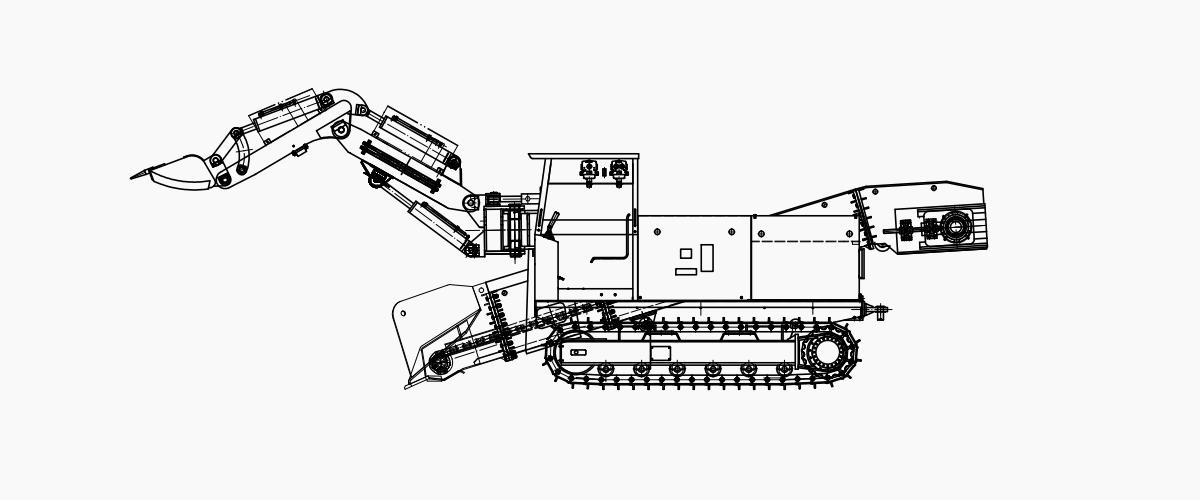

Crawler Mucking Loader for Sale

1.Adaptability to Extreme Slopes – Performs reliably under challenging underground gradients.

2.High-Efficiency Continuous Operation – Ensures long-term, stable, and efficient slag removal.

3.Durable Construction – Reinforced components reduce wear and extend service life.

4.Intelligent Operation – Simplifies control, enhances safety, and improves precision.

5.ROI Optimization – Higher slag output and lower maintenance costs deliver maximum return on investment.

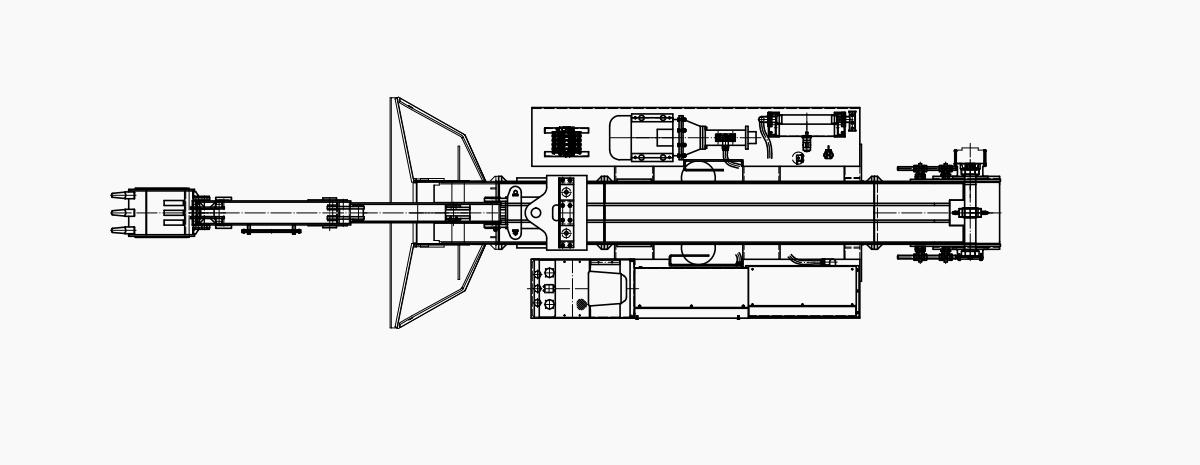

Product Details

Best Crawler Mucking Loader: Key Features & Advantages

The Best Crawler Mucking Loader stands out with high-strength steel structural components, undergoing precise welding for durability. Key vulnerable parts are covered with wear-resistant plates, ensuring stable operation under heavy load, impact, and corrosion—extending service life significantly. It also has a humanized design: an ergono

mic cab and control system reduce operator fatigue, while optimized layout enables flexible steering in narrow underground spaces. A optional cable drum automates cable reeling, cutting labor costs. This Good Crawler Mucking Loader balances performance and efficiency.

Application Scenarios of Best Crawler Mucking Loader

Ideal for underground mines, tunnels, and small-scale construction sites, the Best Crawler Mucking Loader excels in mucking and material handling in harsh, confined environments. It adapts to various terrains, making it a reliable tool for mining projects globally.

Product Advantages

For overseas mining contractors grappling with underground construction pain points—such as steep slope operational risks, frequent equipment downtime, and inflated procurement costs—our factory-direct Crawler Mucking Loader for Sale delivers targeted solutions with three unrivaled strengths, backed by ample inventory and no middleman markup.

First, the heavy-duty crawler chassis grants unrivaled adaptability to extreme underground gradients, eliminating the risk of equipment stalling on steep slopes that plagues traditional models. As a direct manufacturer, we’ve engineered reinforced track components to withstand rugged mine terrain, ensuring reliable slag removal even in the harshest underground environments, with sufficient stock to fulfill urgent project delivery demands.

Second, the loader’s integrated intelligent operation system and durable, factory-calibrated components tackle two critical buyer pain points: high maintenance overheads and operational inefficiency. The simplified smart control panel boosts operational precision and safety, while reinforced core parts cut wear-related downtime by 30%. As a direct factory, we skip intermediaries to offer factory-direct pricing, and our large-scale inventory ensures on-time shipment without supply delays.

Third, the loader’s high-efficiency continuous slag removal capability directly drives ROI optimization for mining projects. Its factory-tuned power system delivers higher slag output per shift, while low-maintenance crawler and component design slashes long-term upkeep costs. With our status as a direct manufacturer, clients avoid middleman price hikes, and our sufficient stock ensures quick delivery to minimize project idle time—turning every unit into a high-return asset for underground mining operations.

Parameter

Item | ZWY-80/30L | ZWY-80/37L | ZWY-80/45L | ZWY-100/45L | ZWY-120/65L | ZWY-150/55L | ZWY-180/75L | ZWY-220/75L | |

Main Technical Parameters | |||||||||

Applicable Section (Width × Height) m | 3.2×2.2 | 3.5×2.5 | 4×2.5 | 4.8×3.2 | 5.4×4.0 | 5.8×4.5 | 6.2×5 | 7.5×5.5 | |

Applicable Axis Width* | (-16° ~ +16°) | (-20° ~ +20°) | ( -32° ~ +32°) | ||||||

Loading Capacity m³/h | 80 | 100 | 120 | 150 | 180 | 220 | |||

Control Mode | Hydraulic Pilot Control | ||||||||

Main Motor Power KW | 30 | 37 | 45 | 55 | 75 | ||||

Digging Width mm | 3200 | 3500 | 4000 | 4600 | 5400 | 5800 | 6200 | 7000 | |

Digging Distance mm | 1500 | 1600 | 1800 | 2150 | 2500 | 3300 | |||

Digging Height mm | 1800 | 2200 | 3000 | 3500 | 3800 | 4000 | 4300 | ||

Digging Depth mm | 400 | 500 | 800 | 990 | 1050 | ||||

Unloading Height (Adjustable) mm | 1200 | 1450 | 2000 | ||||||

Unloading Distance (Adjustable) mm | 1150 | ||||||||

Max. Rotation Angle* | ±36° | ±45° | ±55° | ||||||

Max. Transport Material Size mm | < φ500 | < φ580 | < φ625 | < φ780 | |||||

Boom Structure | Single Boom | Single Boom (or Double Boom) | Double Boom | ||||||

Hoisting Speed m/min | 44 | ||||||||

Track Gauge (Adjustable) mm | 890 | 890 | 900 | 1110 | 1190 | 1400 | |||

Travel Speed m/s | 0.5 | ||||||||

Ground Clearance mm | 300 | ||||||||

Min. Turning Radius m | ≥ 5 | ≥ 7 | ≥ 8 | ||||||

Ground Pressure MPa | ≤ 0.1 | ||||||||

Rated Working Pressure MPa | 23 | ||||||||

Max. Bucket Size | Length mm | 3350 | 4200 | ||||||

Width mm | 850 | 900 | 1000 | 1100 | 1200 | ||||

Height mm | 1200 | 1400 | 1500 | 1650 | |||||

Max. Bucket Weight Kg | 2300 | 3000 | 3500 | ||||||

Max. Overall Dimensions (Working) | Length mm | 6000 | 6500 | 6800 | 7000 | 7500 | 8800 | ||

Width mm | 1750 | 1800 | 2200 | 2350 | 2640 | ||||

Height mm | 1750 | 1750 | 1800 | 2900 | 3250 | 3600 | 3800 | 4200 | |

Machine Weight Kg | 7600 | 8000 | 8200 | 11200 | 13800 | 15200 | 17800 | 20000 | |

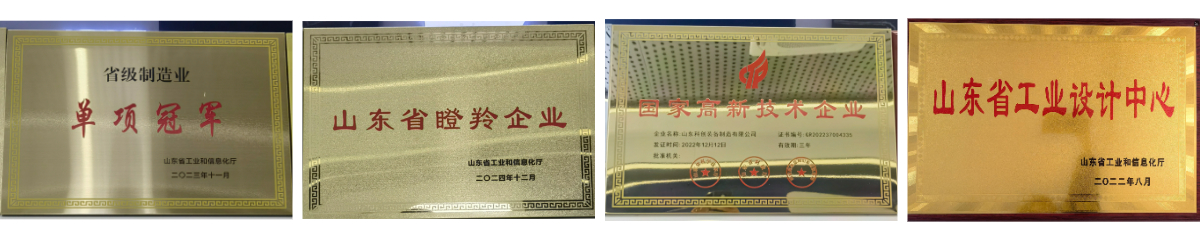

About us

Shandong Cresics Equipment Manufacturing Co.,Ltd. :20 Years of Source Intelligent Manufacturing, Laying a Solid Foundation for International Mining

Founded in 2004, Shandong Kechuang Equipment Manufacturing Co., Ltd. has been deeply engaged in the mining equipment field for more than 20 years. It is one of the few source manufacturers of mining equipment in China that integrates independent design and large-scale manufacturing capabilities.With its strong technical strength and lean production system, the company has successively won a number of authoritative qualifications including Provincial-level Manufacturing Single Champion, Shandong Gazelle Enterprise, National High-tech Enterprise, and Shandong Industrial Design Center. These honors are not only the industry's recognition of its technological leadership, but also the core trust endorsement for international mining customers when selecting equipment.

For international customers focusing on the long-term benefits of mining projects, the strength behind these qualifications is more attractive: as a source manufacturer, Shandong Kechuang can directly connect with customer needs, eliminating the multi-layer markup of intermediate dealers and greatly reducing procurement costs; its independent design team can customize more adaptable equipment such as tracked mucking loaders according to the geological conditions of mines in different countries; at the same time, the large-scale production base ensures sufficient supply of goods, which can quickly respond to the delivery timeliness of overseas orders and avoid project shutdowns caused by equipment shortages.In addition, the R&D foundation of being a national high-tech enterprise can also provide international customers with continuous technical upgrade support, ensuring that the equipment always adapts to the advanced needs of mining operations, truly realizing "one-time procurement, long-term benefits".

FAQ About Best Crawler Mucking Loader

1. What factors affect the Crawler Mucking Loader Price?

Price depends on configurations (e.g., cable drum), customization needs, and order quantity. Contact us for a tailored quote.

2. Why choose this Best Crawler Mucking Loader over others?

It offers superior durability, humanized design, and adaptability—outperforming common models for long-term value.

3. Is after-sales support available for the Good Crawler Mucking Loader?

Yes, we provide global after-sales service, including maintenance guidance and spare parts supply.