Mucking Loader for Sale

1.Ideal for tunnels, mining drifts, water diversion, and defense projects

2.Wide-Track Design: Ensures stable performance in harsh environments

3.Reduces ground pressure and minimizes floor damage

4.Operates smoothly on muddy, soft, or uneven surfaces

5.Easily handles conditions where wheels cannot pass

Product Advantages

The Mucking Loader for Sale can easily handle complex geological conditions such as fault zones and inclined ore bodies, and is particularly suitable for deep mining scenarios.

The Mucking Loader for Sale adopts a modular design. The three major modules of the hydraulic system, conveying device and electrical control can be quickly disassembled and assembled, which is convenient for underground transportation and maintenance. The key components of the Mucking Loader for Sale are made of high-strength manganese steel, with the impact resistance increased by three times. Its operation interface integrates an intelligent display system to monitor parameters such as hydraulic and motor temperatures in real time, and has a self-diagnosis function for faults, significantly reducing the risk of equipment shutdown.

In addition, the Mucking Loader for Sale supports customized modification. The bucket types (such as toothed buckets and flat buckets) can be replaced according to the characteristics of the mineral types to meet the needs of different operations such as phosphate mining, iron ore mining, and copper mining.

Product Details

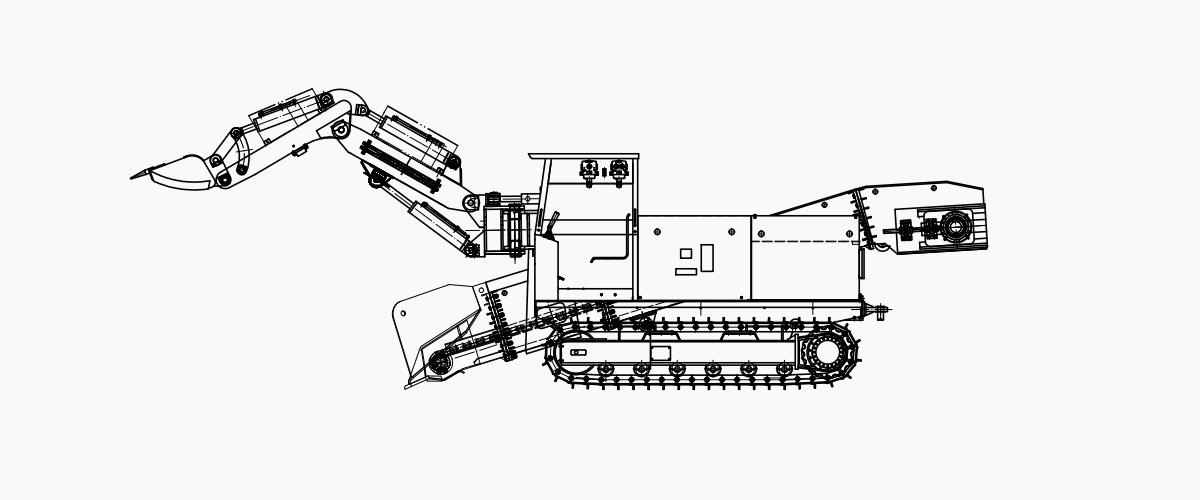

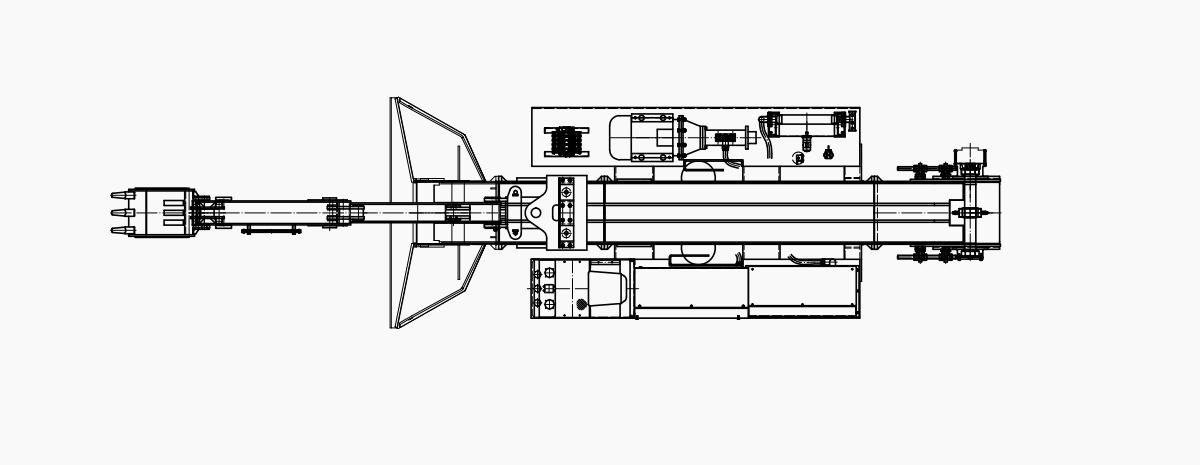

The ZWY series mucking loader machine is composed of seven parts: the hydraulic system, the electrical control system, the working arm, the chassis, the transport trough, the cab system and the frame assembly.

The crawler mucking loader adopts a fully hydraulic crawler structure. It uses a unique backhoe system to scoop up rocks (or ores), and lifts the rocks (or ores) into the central scraper transport trough. Then, the rocks (or ores) are conveyed from the front to the subsequent equipment at the rear (various mine cars, belt conveyors, automobiles, etc.) by the scraper transport mechanism. Meanwhile, The bucket of the mucking loader can also be used to clean the working surface. The crawler walking mechanism is driven by a hydraulic motor, featuring strong performance, strong climbing ability and flexible maneuverability. It can work in damp and waterlogged tunnels.

Parameter

Item | ZWY-80/30L | ZWY-80/37L | ZWY-80/45L | ZWY-100/45L | ZWY-120/65L | ZWY-150/55L | ZWY-180/75L | ZWY-220/75L | |

Main Technical Parameters | |||||||||

Applicable Section (Width × Height) m | 3.2×2.2 | 3.5×2.5 | 4×2.5 | 4.8×3.2 | 5.4×4.0 | 5.8×4.5 | 6.2×5 | 7.5×5.5 | |

Applicable Axis Width* | (-16° ~ +16°) | (-20° ~ +20°) | ( -32° ~ +32°) | ||||||

Loading Capacity m³/h | 80 | 100 | 120 | 150 | 180 | 220 | |||

Control Mode | Hydraulic Pilot Control | ||||||||

Main Motor Power KW | 30 | 37 | 45 | 55 | 75 | ||||

Digging Width mm | 3200 | 3500 | 4000 | 4600 | 5400 | 5800 | 6200 | 7000 | |

Digging Distance mm | 1500 | 1600 | 1800 | 2150 | 2500 | 3300 | |||

Digging Height mm | 1800 | 2200 | 3000 | 3500 | 3800 | 4000 | 4300 | ||

Digging Depth mm | 400 | 500 | 800 | 990 | 1050 | ||||

Unloading Height (Adjustable) mm | 1200 | 1450 | 2000 | ||||||

Unloading Distance (Adjustable) mm | 1150 | ||||||||

Max. Rotation Angle* | ±36° | ±45° | ±55° | ||||||

Max. Transport Material Size mm | < φ500 | < φ580 | < φ625 | < φ780 | |||||

Boom Structure | Single Boom | Single Boom (or Double Boom) | Double Boom | ||||||

Hoisting Speed m/min | 44 | ||||||||

Track Gauge (Adjustable) mm | 890 | 890 | 900 | 1110 | 1190 | 1400 | |||

Travel Speed m/s | 0.5 | ||||||||

Ground Clearance mm | 300 | ||||||||

Min. Turning Radius m | ≥ 5 | ≥ 7 | ≥ 8 | ||||||

Ground Pressure MPa | ≤ 0.1 | ||||||||

Rated Working Pressure MPa | 23 | ||||||||

Max. Bucket Size | Length mm | 3350 | 4200 | ||||||

Width mm | 850 | 900 | 1000 | 1100 | 1200 | ||||

Height mm | 1200 | 1400 | 1500 | 1650 | |||||

Max. Bucket Weight Kg | 2300 | 3000 | 3500 | ||||||

Max. Overall Dimensions (Working) | Length mm | 6000 | 6500 | 6800 | 7000 | 7500 | 8800 | ||

Width mm | 1750 | 1800 | 2200 | 2350 | 2640 | ||||

Height mm | 1750 | 1750 | 1800 | 2900 | 3250 | 3600 | 3800 | 4200 | |

Machine Weight Kg | 7600 | 8000 | 8200 | 11200 | 13800 | 15200 | 17800 | 20000 | |

About us

Shandong Kechuang Equipment: Solve Your Mining Equipment Procurement Pain Points with Core Strengths For global mining enterprises, delayed equipment delivery, sky-high intermediate costs, inflexible customization, and unstable product quality are long-standing procurement pain points. Shandong Kechuang Equipment Manufacturing Co., Ltd., a leading source factory in Tai’an, Shandong, addresses these pain points head-on with four core advantages. Boasting independent R&D and independent design capabilities, we offer customized solutions for complex mining conditions, from roadheader adaptations to side-dump rock loader upgrades, eliminating reliance on third-party technologies. Our large-scale production base ensures stable supply, with stock ready to fulfill urgent orders and avoid project delays. As a direct manufacturer, we realize cost control by cutting middleman margins, delivering high-value equipment at competitive prices. A strict full-process quality control system, from component inspection to factory testing, guarantees each device meets international standards, making us your reliable mining equipment partner.