Why Choose Side-Discharge Rock Loaders for Underground Coal Mine Clearance Operations?

Core Advantages and Features

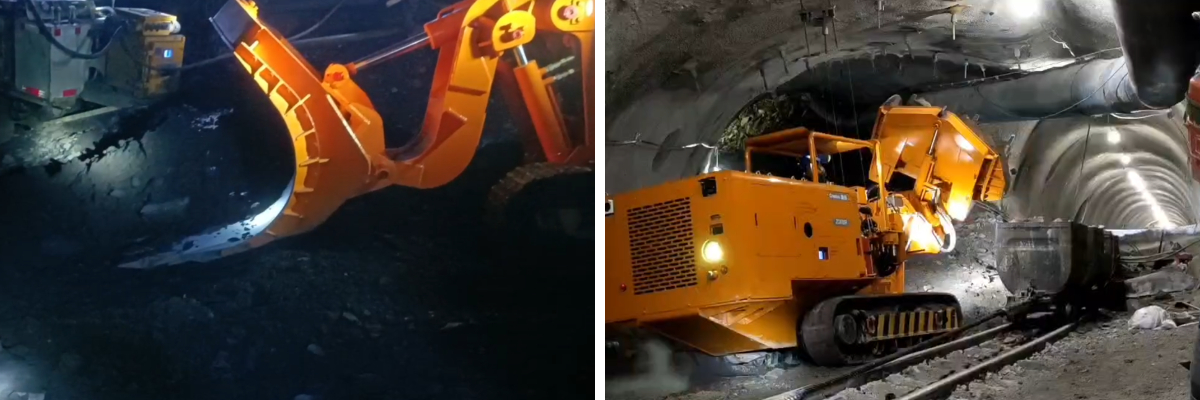

In complex underground coal mining environments, efficiency, safety, and versatility form the multifaceted considerations when selecting underground equipment. When it comes to clearing debris and rubble after blasting in small-section, solid-rock tunnels, the Downhole Side Unloading Rock Loader has become the unparalleled choice for boosting operational efficiency. Unlike traditional front-end loaders, this equipment ingeniously relocates the unloading mechanism to the side of the loading bucket. This design enables seamless loading operations within confined spaces. Additionally, the Coal Mine Side Unloading Rock Loader serves multiple purposes: functioning as a support platform, facilitating short-distance material transport, and—when equipped with a replacement working unit like a breaker hammer—crushing large rock fragments. Why choose a side-discharge rock loader for mining operations? This article delves into its indispensable core advantages and features—from flexible loading/unloading capabilities to customizable designs—ensuring seamless integration with your coal mine tunnel workflows.

Unmatched Maneuverability in Confined Spaces

The core challenge in underground coal mining lies in space—more precisely, the scarcity of underground space. Traditional loaders often struggle to unload effectively due to limited steering capabilities, making operations in narrow tunnels both hazardous and time-consuming. Additionally, their front-loading/front-unloading design wastes significant time maneuvering the machine to discharge rock and coal chunks. The Downhole Side Unloading Rock Loader solves this problem through innovative design. Its ability to discharge material laterally (typically at a 90-degree angle to the body) allows unloading without turning the entire machine. This enables direct feeding to conveyors or skip cars alongside the tunnel, enhancing loading/unloading efficiency and transforming previously wasted unloading time into productive working hours. Core Advantage: The turning radius of the Coal Mine Side Unloading Rock Loader is significantly smaller than that of rear-discharge loaders. It can even load and unload without turning in narrow tunnels. This core advantage makes it the optimal choice for coal mine tunnel workfaces.

Superior Loading Efficiency and Power Output

In underground coal mining operations, time is money, and every second of the loading cycle counts. The Downhole Side Unloading Rock Loader is engineered for high-efficiency production, featuring an electric-hydraulic system design that generates immense digging force, enabling the bucket to effortlessly penetrate hard blasted rock piles. Current models feature multiple lifting cylinders that, through optimized control, minimize the cycle time between digging and unloading. For instance, certain Customized Side Dump Rock Loader models not only feature oversized bucket capacities (typically exceeding 1 cubic meter) but also incorporate high-power, high-pressure hydraulic circuits. This allows the equipment to maintain superior performance even under heavy-load working conditions. This significantly boosts overall production output when using Coal Mine Side Unloading Rock Loader units, commonly measured in tons produced per shift.

Multifunctionality: One Machine, Multiple Uses

Another core advantage of Coal Mine Side Unloading Rock Loader units lies in their “one machine, multiple uses” capability. In confined underground coal mines, dedicating specialized equipment for each task is often impractical and increases mining costs. After completing primary loading tasks, the Downhole Side Unloading Rock Loader can transition into a support auxiliary vehicle. Its sturdy unloading platform serves as an elevated work platform for roof bolt installation or maintenance operations. Additionally, it can perform:

● Short-distance transport: Moving tools and supplies

● Tunnel cleaning (wet operations): Clearing debris from tunnel floors

● Wall cleaning: Removing loose, hazardous material from tunnel walls. This versatility of the Downhole Side Unloading Rock Loader reduces reliance on multiple machines for mining operations, streamlining workflows and lowering costs.

Safety First: Engineered for Complex and Hazardous Underground Environments

Ensuring safety is the paramount priority in coal mining operations, particularly in production settings where combustible gases like methane and flammable coal dust are present. The Downhole Side Unloading Rock Loader is specifically engineered with safety as the primary consideration. All equipment features an explosion-proof (Ex) design, equipped with dedicated explosion-proof motors and electrical systems to effectively prevent sparks from electrical components that could endanger the work environment. Hydraulic systems typically incorporate explosion-proof isolation devices and flame-retardant hydraulic fluid. Furthermore, this Coal Mine Side Unloading Rock Loader holds China Coal Mine Safety Equipment Certification. Its design substantially reduces operational demands in hazardous coal mining faces, significantly lowering accident risks. For mines with low-clearance tunnels, Customized Side Dump Rock Loader solutions are available to ensure safe operation in low-seam environments.

Customization and Durability

Each mine possesses unique production conditions. Geological variations are substantial—ranging from damp and muddy to dry and dusty environments, and from soft coal seams to hard rock mining. Customized Side Dump Rock Loader models demonstrate distinct advantages in this regard. Manufacturers recognize that standard models cannot meet every coal mine's requirements, enabling tailored solutions for each site's specific conditions and needs:

● Track width: Adjusted for stability on rugged terrain.

● Bucket design: Optimized for different material types (coal seams and hard rock).

● Dimensions: Compact versions available for extremely narrow roadways. Downhole Side Unloading Rock Loader units are constructed from high-strength steel and often feature wear plates to withstand abrasion from rock and coal. This robust construction ensures round-the-clock operation even in the harshest environments, maintaining long-term equipment durability.

Conclusion

To sum up, the underground side-discharge rock loader has long transcended the scope of a single mechanical device. In essence, it is a core comprehensive solution to solve the problems of modern underground coal mining. With its unparalleled operational efficiency in narrow tunnels and intrinsically safe explosion-proof design, it has completely redefined the standards for loading operations. Whether you are a standard Coal Mine Side Unloading Rock Loader that needs to be put into production immediately or a Customized Side Dump Rock Loader for deep grinding under special working conditions, this is an investment that can produce immediate results - it directly translates into a safer working environment, soaring production efficiency and highly competitive operating costs. In the process of moving towards intelligent and mechanized mines, it is undoubtedly a pillar without a doubt.