Low Type Side Dump Rock Loader

1. Professional construction assistant

High-torque crawler drive device ensures efficient material transfer across the entire section.

2.Example of performance upgrade

The equipment bucket has lifting and transportation capabilities and can handle super-large supporting materials such as tires.

The deep cleaning system realizes the mechanization of the entire loading process, which can greatly improve the operational efficiency of the working conditions.

Product Details

The ZCY120R Side Dump Rock loader is specially designed for complex working conditions in coal mines. It is equipped with a 55kW explosion-proof motor to achieve an efficient loading capacity of 120m3/h. Its 1876mm wide bucket and 2000mm maximum unloading height can easily handle coal, semi-coal rock and small-section full-rock tunnel operations. Crawler-type traveling mechanism, ±16° climbing ability and 200mm ground clearance ensure stable altitude. Innovative integrated support platform function, the bucket can be used as a temporary working platform after being lifted, and combined with the multi-purpose functions of short transportation, undercover cleaning, etc., it can significantly improve the excavation efficiency and reduce labor costs by more than 30%.

Product features

1. Ultra-low body design, suitable for extremely narrow Spaces

The machine body height is as low as 2 meters, allowing it to easily enter thin coal seams, low tunnels and complex cross tunnels for operation. The compact structure of the equipment, combined with its 360-degree flexible steering capability, enables efficient loading and obstacle avoidance in narrow Spaces, solving the problem of traditional equipment being unable to "enter and turn".

2. 90-degree lateral rapid unloading enhances the efficiency of transportation connection

The hydraulically driven side unloading system is adopted, with an unloading Angle of up to 90 degrees. Materials can be directly side-unloaded onto mine cars, belt conveyors or scraper conveyors, avoiding the time-consuming operation of repeatedly adjusting the vehicle position required by traditional rear unloading equipment. The single-cycle unloading time is 40% shorter than that of the post-unloading type. Combined with a large-capacity bucket (3-6 cubic meters), it can load 400-600 tons of materials per hour, significantly enhancing the overall efficiency of the underground transportation system.

Parameters

Product Model | ZCY45R | ZCY60R | ZCY80R | ZCY100R | ZCY120R | |

Technical Bucket Capacity (m³) | 0.45 | 0.60 | 0.80 | 1.00 | 1.2 | |

Main Motor Power (kW) | 30 | 45 | 55 | |||

Voltage (V) | 660/1140 | 660/1140 | ||||

Bucket Width (mm) | 1370 | 1520 | 1696 | 1696 | 1876 | |

Maximum Dumping Height (mm) | ≥1460 | ≥1320 | ≥1600 | ≥1900 | ≥2000 | |

Maximum Digging Depth (mm) | ≥400 | ≥400 | ≥400 | ≥500 | ≥500 | |

Gradeability (°) | ≥16 | ≥16 | ≥16 | ≥16 | ≥16 | |

Traction Force (kN) | ≥20 | ≥20 | ≥40 | ≥40 | ≥40 | |

Minimum Ground Clearance (mm) | ≥180 | ≥180 | ≥200 | ≥200 | ≥200 | |

Maximum Travel Speed (m/s) | ≥0.5 | ≥0.5 | ≥0.81 | ≥0.81 | ≥0.81 | |

Working Mechanism Pressure (MPa) | 16±0.5 | 16±0.5 | 16±0.5 | 16±0.5 | 16±0.5 | |

Travel Motor Pressure (MPa) | 22±0.5 | 22±0.5 | 22±0.5 | 22±0.5 | 22±0.5 | |

External Oil Port Pressure (MPa) | 20±0.5 | |||||

Noise (Sound Pressure Level) (dB) | ≤90 | |||||

Center of Gravity Position | Xg=635 | Xg=650 | Xg=710 | Xg=750 | Xg=780 | |

Track Ground Pressure (MPa) | 0.09 | 0.1 | ||||

Overall Dimensions | Length (mm) | 4490 | 4580 | 5100 | 5330 | 5370 |

Width (mm) | 1425 | 1520 | 1696 | 1696 | 1876 | |

Height (mm) | 2046 | 2046 | 2100 | 2300 | 2300 | |

Dry Weight(kg) | 4500 | 4650 | 7350 | 8300 | 8500 | |

Application scenarios

1. Fully mechanized mining/blasting excavation work face

The side-unloading rock loading machine can quickly clear the coal gangue and rocks after blasting and directly side-unload them into the scraper conveyor, belt conveyor or mine car, achieving a seamless connection of "loading - transportation".

Advantages: It reduces the time required for traditional rear-unloading equipment to repeatedly adjust parking Spaces, and shortens the single-cycle operation time by more than 30%. The bucket has a large capacity and, in combination with a high-power hydraulic system, can load 300 to 500 tons of materials per hour, meeting the demands of high-yield and efficient mines.

2. Work in thin coal seams and narrow Spaces

The low-profile side-unloading rock loader can enter 1.6-meter-high tunnels, solving the problem that traditional equipment cannot operate.

Advantages: The crawler-type walking mode enhances the ground grip force, allowing for smooth movement on slopes with a gradient of less than 65 degrees or in mine tunnels. The hydraulic drive device can load and unload heavy minerals and huge rocks.

About us

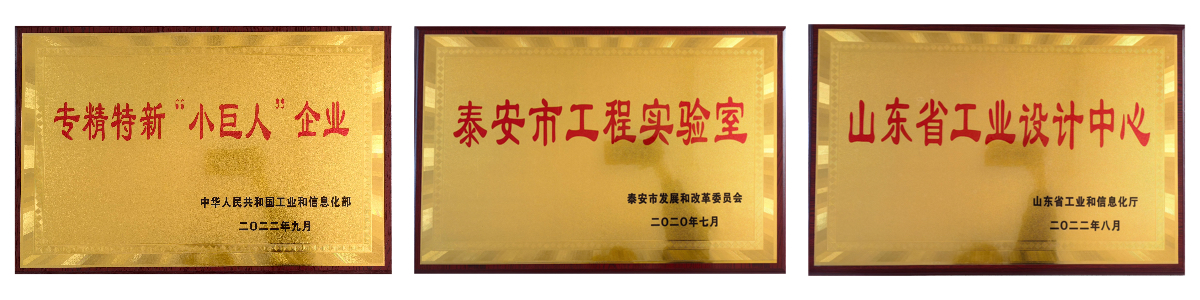

In recent years, Shandong Cresics Equipment Manufacturing Co., Ltd. has demonstrated outstanding innovation capabilities and profound technical accumulation in the field of patents. Up to now, the company has obtained over 50 patent certificates in total, with invention patents accounting for more than one-third. These patents cover core technical fields such as intelligent control of mining equipment, high-efficiency and energy-saving transmission systems, and safety protection devices, forming a full-chain patent layout covering product research and development, production and manufacturing, and safe application. The company has established a complete R&D and innovation system, and has set up a cooperation mechanism of industry-university-research with many universities and research institutions. The average annual R&D investment accounts for 8% of its revenue, and it continuously promotes technological iteration and upgrading. Its patented achievements are not only widely applied in the independently developed coal safety certification equipment, but also have led and participated in the formulation of three industry standards, promoting the standardized development of industry technology. Through cross-licensing of patents and technology transformation, the company has achieved the industrial application of multiple core patents. The market share of its products has ranked among the top in the industry for five consecutive years, fully demonstrating its strategic determination and leading position in the industry to drive development through technological innovation.

Frequently Asked Questions (FAQ)

Q1:What is the maximum unloading height and Angle of the low-profile side-unloading rock loader? Can it adapt to transportation equipment of different heights?

The unloading height of the low-profile side-unloading rock loader is usually designed at 2 to 2.5 meters. Its core advantage lies in the flexible adjustment of the unloading height through the hydraulic system, and the unloading Angle can reach 90 degrees (lateral unloading).

Low tunnel operation: Materials can be directly unloaded onto mine cars or belt conveyors by reducing the unloading height, avoiding secondary transfer.

High transportation equipment connection: In a 3-meter-high tunnel, the unloading height is raised to connect with the main transportation belt conveyor, achieving continuous operation.

Case: After a low-profile side-unloading rock loader was used in a certain mine in Shaanxi Province, the adaptability of unloading height increased by 40%, and the single-shift transfer efficiency rose by 25%.

Q2: How durable is the equipment in a damp or corrosive mine environment? What is the maintenance cycle?

The low-profile side-unloading rock loader is made of high-strength wear-resistant steel for the bucket and key components. The surface is phosphated for rust prevention and is equipped with a sealed hydraulic system, which can effectively resist damp and corrosive environments.

Structural service life: It can be continuously used in sulfur-containing mines for more than 5 years without severe rust.

Hydraulic system: Anti-wear hydraulic oil and explosion-proof valve groups are adopted, reducing the failure rate by 30% compared with traditional equipment.

Maintenance cycle

Daily inspection: Check the hydraulic oil level, tire pressure and the tightness of key bolts at each shift.

Regular maintenance: Replace the hydraulic oil and filter element every 500 hours, and inspect the bearings and seals every 1000 hours.

Case: After a high-gas mine in Inner Mongolia adopted the explosion-proof low-profile side-unloading rock loader, it did not shut down due to corrosion for three consecutive years, and the maintenance cost decreased by 20%.